Spray Smarter, Grow the Future

Spray Smarter, Grow the Future

SINOSO Multi-function Orchard Robots are revolutionizing modern farming practices. These advanced Agricultural Robots, such as the 200 Multi-function Orchard Robot and the 400 Multi-function Orchard Spraying Robot, provide reliable autonomous solutions for spraying, harvesting, and more. Experience enhanced efficiency with features like:

|

Feature |

Metric |

|---|---|

|

Coverage Efficiency |

5.93 acres per hour |

|

Spraying Range |

Up to 15 meters wide |

|

Terrain Adaptability |

Crawler chassis, strong climb |

Powered by SINOSO’s cutting-edge technology, these multi-function orchard robots offer precise navigation, modular tool compatibility, and adaptive spraying systems that reduce labor, lower chemical usage, and improve safety across your agricultural operations.

Multi-function orchard robots like the SINOSO SOROB 200 perform many tasks such as spraying, weeding, and harvesting, saving time and reducing the need for multiple machines.

These robots improve safety by handling dangerous jobs like chemical spraying, reducing workers' exposure to harmful substances and physical strain.

Autonomous navigation and smart sensors help robots work efficiently on uneven terrain and tight orchard rows, increasing productivity and lowering labor costs.

Precision spraying and targeted treatments cut chemical use by up to 40%, protecting the environment and lowering expenses.

Robotic harvesters deliver consistent fruit picking with high accuracy, and modular designs allow quick switching between tasks to adapt to changing orchard needs.

You can achieve enhanced efficiency in your orchard by adopting a multi-function orchard robot. These robots combine autonomous mobility, intelligent sensors, and precision manipulators to perform tasks such as weeding, spraying, and harvesting. You no longer need several specialized machines for different jobs. The modular design allows you to switch tools quickly, so you can handle weeding, transport, or tillage with one platform. Farm robots like the SINOSO SOROB 200 operate on a compact crawler chassis, which navigates tight orchard rows and uneven terrain with ease.

Automation streamlines repetitive tasks, reducing labor intensity and operational complexity. You benefit from reduced labor costs and improved resource allocation. Robots equipped with AI and self-learning algorithms adapt to changing crop geometries and environmental conditions. This adaptability supports year-round use, increasing utilization rates and return on investment. Real-world deployments show that multi-function orchard robots deliver measurable efficiency gains, such as a 40% reduction in chemical usage and significant savings in soil analysis costs.

|

Feature |

Benefit |

|---|---|

|

Modular Expansion |

Multi-task capability |

|

Compact Design |

Easy navigation, low cost |

|

All-Terrain Chassis |

Reliable operation anywhere |

|

Precision Spraying |

Reduced waste, better yields |

Farm robots play a key role in risk mitigation. You can minimize workplace accidents by using robots with ergonomic designs and safety-focused engineering. Smaller, lighter machines reduce physical strain compared to heavy tractors. Robots handle hazardous tasks like spraying chemicals, so you avoid direct exposure. Features such as autonomous navigation, remote monitoring, and smart alerts further enhance safety.

You benefit from collaborative robots that work alongside humans, supporting natural cooperation in complex orchard environments. These robots help prevent musculoskeletal disorders by taking on repetitive motions and heavy lifting. Safety assurance systems and intelligent communication reduce unwanted contact and optimize field operations. By integrating these features, multi-function orchard robots protect workers and support sustainable agriculture.

You can transform your orchard management by using autonomous robots for repetitive tasks. Farm robots like the SINOSO SOROB 200 automate spraying, weeding, transport, and tillage. You no longer need to rely on manual labor for these time-consuming operations. Autonomous weeding robots use advanced sensors to detect weeds and apply targeted treatments. This approach increases precision and reduces chemical usage. You benefit from robots that navigate orchard rows, identify crops, and avoid obstacles. These machines work together, optimizing task allocation and adapting to changing field conditions.

Robots automate spraying with patch and canopy sprayers, reducing pesticide use by up to 50%.

Autonomous weeding robots perform mechanical and thermal weed control, improving operation quality.

Transport robots move harvested fruit efficiently, saving time and labor.

Decision-making algorithms coordinate multiple robots, ensuring smooth operations and resource allocation.

You achieve better resource optimization by deploying autonomous robots in your orchard. Adaptive path planning and GNSS navigation allow robots to follow precise routes, minimizing wasted movement and energy. Robots use octree-based 3D point cloud optimization and improved RRT algorithms to enhance path smoothness and reduce path length. These technologies increase planning speed and sampling point utilization, making your operations more efficient.

GNSS navigation provides accurate coverage paths for robots, enabling precise spraying, weeding, and harvesting. Sensor fusion with LiDAR and vision systems improves navigation accuracy, especially under dense canopies. Robots use global orchard maps generated from UAV imagery and deep learning to detect tree rows and plan efficient routes. This approach reduces manual effort and optimizes vehicle movement.

You optimize resource usage by adopting specialized canopy architectures, such as V-shaped or fruiting-wall designs. These structures improve fruit accessibility and harvesting efficiency for robots. Human-robot collaboration further enhances productivity, allowing you to handle unpredictable situations and service robotic subsystems. Advanced scheduling algorithms manage work schedules, battery recharging, and pesticide refills, reducing downtime and unnecessary movements.

|

Aspect |

Data / Example |

Source / Person |

|---|---|---|

|

Labor cost composition |

Labor accounts for ~60% of production costs; 50% of labor costs are harvesting costs |

Mitch McNab |

|

Labor efficiency |

One employee can operate up to 5 tractors simultaneously using driverless technology |

Connor Kingman |

|

Labor reduction in packing |

Automation reduces manual labor needs in packing lines and pruning |

Heidi Morris |

|

Chemical application data |

Detailed spray application data captured via Agworld software enables compliance and chemical reduction per acre |

Heidi Morris |

|

IoT devices for chemical optimization |

Electronic insect traps and pheromone dispensers (Semios system) provide data to optimize chemical use and timing |

Semios CEO Dr. Michael Gilbert |

|

Robotic harvesting trials |

Robotic apple picking trials aim to reduce labor needed for harvesting |

Mitch McNab |

|

Automation impact on labor |

Automation empowers staff to work smarter, reducing need for additional seasonal labor |

Heidi Morris |

You see measurable outcomes from these innovations. Labor costs decrease as robots handle harvesting and weeding. Chemical usage drops due to precision application and data-driven scheduling. Throughput increases because robots operate 24/7, unaffected by fatigue or weather. You experience time-saving operations and improved operation quality across all aspects of orchard management.

You face significant risks when working with chemical pesticides in orchards. Manual spraying exposes you to agrochemicals, which can lead to health problems over time. Autonomous sprayers change this reality. These machines operate independently, keeping you away from direct contact with hazardous substances. You control the process remotely, allowing the autonomous sprayers to handle the application with precision.

A scientific study compared manual spraying with automated mobile robotic sprayers in orchard-like environments. The results showed that autonomous sprayers lowered physiological stress indicators for workers. Heart rate dropped by 25%, work pulse by 75%, oxygen consumption by 42%, and energy expenditure by 41%. Manual spraying caused three to six times higher discomfort and cardiac cost. Autonomous sprayers help you avoid these health hazards and reduce your exposure to chemicals.

You benefit from targeted spraying technology. Autonomous sprayers use adaptive pressure systems and oscillating nozzles to deliver chemicals only where needed. This approach minimizes drift and ensures full leaf coverage. You see a 40% reduction in chemical usage, which means less exposure for you and your team. Smart sprayers also support anti-residue systems, further lowering the risk of accidental contact.

You encounter physical risks when operating heavy machinery or performing repetitive tasks in orchards. Autonomous sprayers address these challenges by taking over dangerous jobs. You no longer need to lift heavy tanks or navigate uneven terrain with manual equipment. Autonomous sprayers move on crawler platforms, climbing slopes and crossing rough ground without human intervention.

Remote monitoring gives you control over autonomous sprayers from a safe location. You receive real-time alerts about equipment status, battery levels, and chemical quantities. If a problem occurs, such as low battery or empty tank, the autonomous sprayers trigger auto-return functions. The machines navigate back to supply points automatically, reducing the chance of accidents.

You rely on smart alerts to stay informed about anomalies. Sensors detect malfunctions, environmental changes, or obstacles. Autonomous sprayers notify you instantly, allowing you to respond quickly and prevent injuries. You do not need to be physically present in hazardous areas, which lowers your risk of slips, falls, or chemical spills.

Current literature does not provide historical injury data for autonomous orchard robots. However, safety principles suggest that removing human operators from hazardous tasks reduces injury risk. Autonomous sprayers create physical distance between you and potential dangers. You benefit from advanced safety hierarchies that prioritize your well-being.

|

Safety Feature |

How It Protects You |

|---|---|

|

Remote Monitoring |

Keeps you informed and away from hazards |

|

Auto-Return |

Prevents accidents during low battery events |

|

Smart Alerts |

Enables quick response to anomalies |

|

Crawler Platform |

Handles rough terrain without human effort |

|

Targeted Spraying |

Reduces chemical drift and exposure |

You must follow strict safety regulations when applying chemicals in orchards. Autonomous sprayers help you meet these standards. These machines use AI targeting, drift reduction, and operator safety interlocks to protect you and the environment. International standards, such as ISO18497:2018, set safety principles for highly automated agricultural machines. Autonomous sprayers include obstacle detection and alarms to safeguard humans and animals.

Regulatory frameworks, like California OSHA guidelines, allow autonomous equipment under supervision, especially for pesticide application. This reduces your chemical exposure and supports compliance. The EU legal framework requires harmonized standards and CE marking, showing that autonomous sprayers meet safety directives.

Autonomous sprayers use embedded sensors to monitor vibration, tilt, voltage, and overload. Geofencing prevents entry into restricted zones. Environmental sensors track chemical levels and air quality, helping you respond quickly to emergencies. Best practices recommend regular training and maintenance to ensure autonomous sprayers operate safely.

Autonomous sprayers incorporate advanced safety features to protect you and your team.

International and national regulations support the use of autonomous sprayers for safer orchard management.

Embedded sensors and smart alerts enhance real-time hazard detection and compliance.

You can rely on harvesting robots like the SINOSO SOROB 200 to transform your orchard’s productivity. These machines use advanced vision systems and precise manipulators to identify, locate, and pick fruit with impressive accuracy. When you deploy a robotic harvester, you benefit from consistent performance and reduced labor needs. The SOROB X expansion modules allow you to switch between harvesting and transport tasks, making your operations more flexible.

Key metrics help you evaluate the effectiveness of harvesting robots:

Fruit Picking Efficiency (FPE): Measures the percentage of marketable fruits harvested.

Fruit Picking Throughput (FPT): Tracks the average number of fruits picked per unit time.

Precision and Recall: Assess the robot’s ability to detect and classify fruit.

Mean Average Precision (mAP): Indicates detection performance across fruit types.

F1 Scores: Show the balance between precision and recall.

Instance Segmentation Accuracy: Evaluates how well the robot separates individual fruits.

Intersection over Union 3D (IoU3D): Measures the accuracy of 3D fruit localization.

Economic Viability: Considers picking speed, damage rates, and profitability.

You can see the robot’s performance in the table below:

|

Metric |

Value(s) |

Description/Notes |

|---|---|---|

|

Harvesting Success Rate |

92% |

Percentage of fruits successfully harvested |

|

Damage Rate |

0% |

Percentage of fruits damaged during harvest |

|

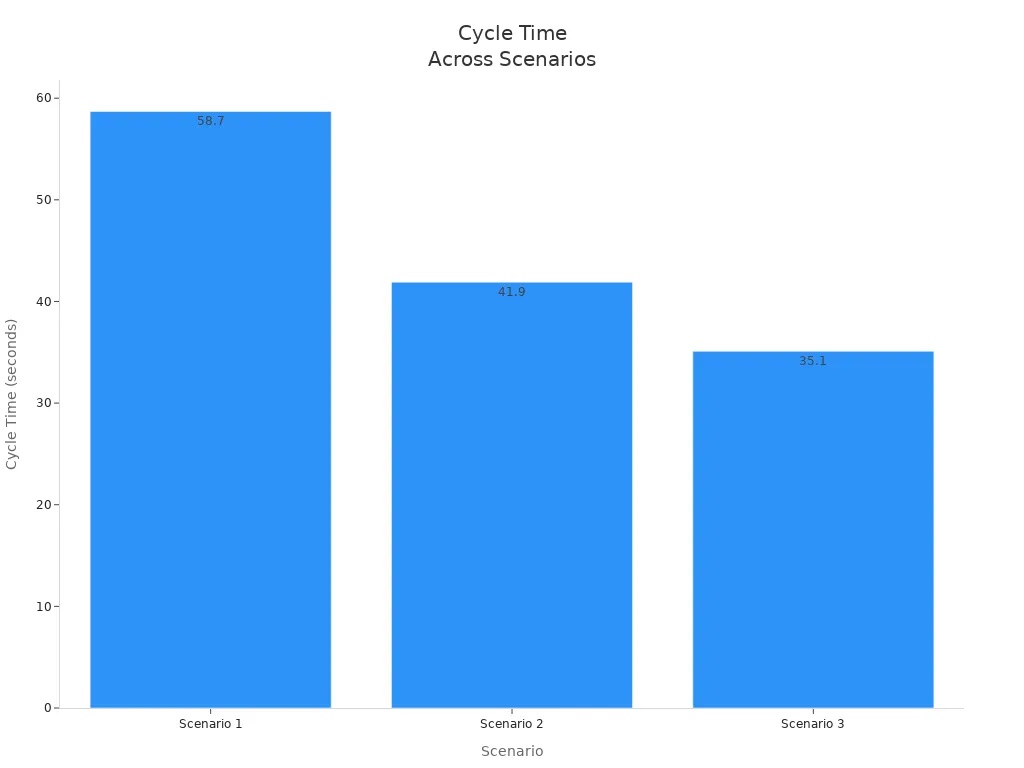

Cycle Time |

58.7s, 41.9s, 35.1s |

Average time per harvesting cycle |

|

Accuracy |

4.5 mm |

Positional accuracy of the robot |

|

Repeatability |

5.23 mm |

Consistency of repeated movements |

|

System Resolution |

1 mm (x,y,z) |

Minimum motion increment |

You can also visualize the improvement in cycle times across different scenarios:

When you compare harvesting robots to traditional methods, you notice some differences. Manual harvesting remains faster and more flexible, but robots are catching up in accuracy and adaptability. For example:

|

Aspect |

Orchard Robots (Apple Harvesting) |

Traditional Harvesting Methods |

|---|---|---|

|

Recognition Rate |

Approximately 81.73% to 85% |

Generally higher due to human perception |

|

Harvesting Rate |

Around 86.92% |

Typically near 100% (manual picking) |

|

Harvesting Time |

9.5 to 15 seconds per fruit |

Faster than robots (manual picking speed) |

|

Adaptability |

Enhanced by intelligent computing and vision systems; can operate autonomously, even at night |

High adaptability due to human flexibility |

|

Operational Flexibility |

Limited by hardware; improving with new algorithms |

High flexibility and speed |

With the SOROB X modules, you can expand your system to include automated harvesting and transport. This flexibility means you can adapt quickly to changing conditions and maximize your yield throughout the season. SINOSO, a global leader in precision agriculture and intelligent water management, continues to innovate in this field. You benefit from AI-powered solutions that optimize your productivity and support sustainable, high-yield farming.

Leave a Message