Farmers think orchard robot technology will change farming. Orchard robots help save money and work faster. Robots pick fruit carefully and waste less. These machines also help the environment. Knowing how orchard robot systems work helps growers choose well for their farms.

Orchard Robot Benefits

Efficiency

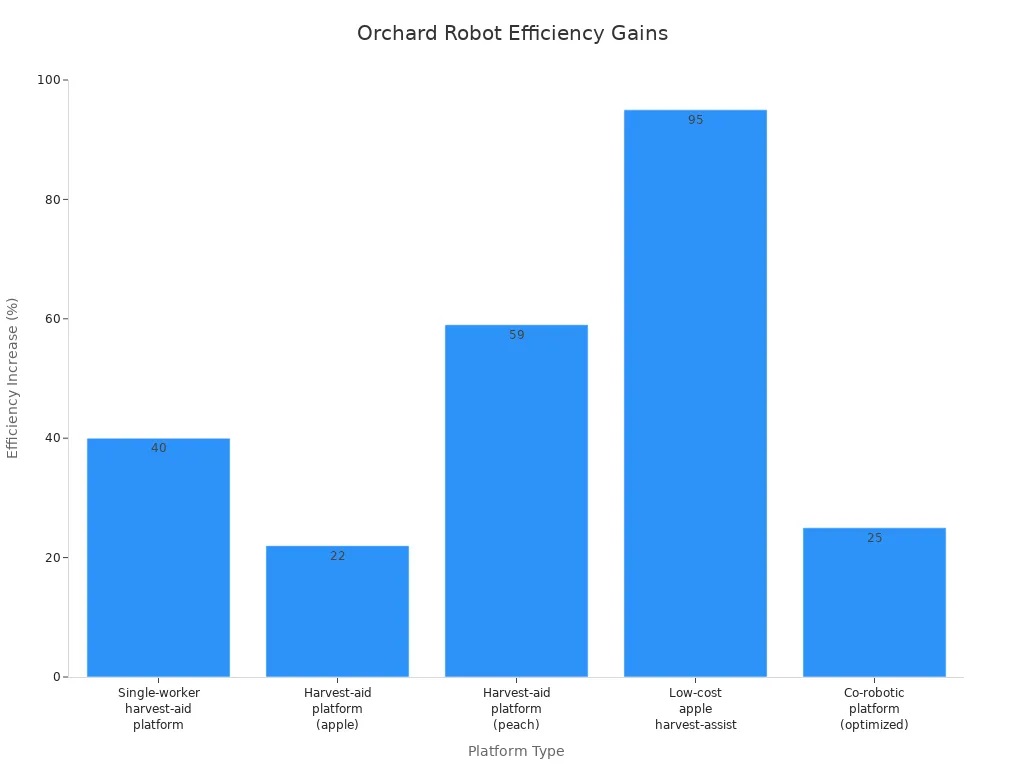

Orchard robots help farms work faster when picking fruit. These machines can do jobs quicker than people in many cases. For example, co-robotic platforms pick apples 11% to 25% faster. Peach picking gets a 59% boost with harvest-aid platforms. Some cheap apple harvest-assist units almost double the speed in high branches. The table below shows how each platform does compared to people:

|

Method/Platform Type |

Crop/Context |

Efficiency Improvement Compared to Manual Methods |

|---|---|---|

|

Single-worker harvest-aid platform |

Citrus picking |

40% increase in picking rate |

|

Harvest-aid platform (apple picking) |

Apple |

Up to 22% improvement |

|

Harvest-aid platform (peach picking) |

Peach |

59% increase |

|

Low-cost apple harvest-assist unit |

Apple (upper tree) |

95% increase |

|

Co-robotic platform (optimized speed and vertical positioning) |

Apple (harvest throughput) |

11% to 25% increase depending on stem clipping |

Orchard robot systems do the same jobs over and over. They help farms run well and keep workers safe, even on long days. This better efficiency means farms spend less money and use their supplies wisely.

Labor Savings

Orchard robots mean farms need fewer people for picking. Farms using robots spend much less time working per acre. Picking by hand takes about 120 hours for each acre. With robots, picking plus hand checking takes about 63.57 hours per acre. This saves almost 64.43 hours for every acre. Over five years, farms can cut labor costs by up to 25%. These savings help farms stay strong and deal with not enough workers.

Fruit Quality

Robots pick fruit gently and carefully. Many orchard robots get over 80% accuracy when picking. Some apple robots reach 84.3% precision and an F1-score of 0.81. In lychee picking, robots can be 93.2% accurate in good conditions. High accuracy means less fruit gets hurt or wasted. Robots also keep fruit cleaner by touching it less, so there is less chance of spreading disease.

Data Insights

Orchard robots gather important data while they work. They use sensors and cameras to check plant health, soil wetness, light, and temperature. Robots find pests and diseases, watch growth, and map how much fruit is picked. Here are some kinds of data robots collect:

-

Plant health and growth rates

-

Soil moisture and temperature

-

Light levels in the orchard

-

Disease and pest presence

-

Irrigation needs

-

Yield mapping and navigation data

This data helps farmers decide when to fertilize, spray, prune, and water. With these facts, farms can grow more and waste less.

Sustainability

Orchard robots help farms be more earth-friendly. They use smart sensors and AI to put fertilizer and pesticides only where needed. This stops too much use and keeps water clean. Robots also keep workers safe by handling chemicals. By using fewer chemicals and managing supplies better, orchard robots help farms care for nature and keep crops healthy. These steps save money and make farming better for the future.

Challenges for Orchard Robots

Upfront Costs

Many growers find orchard robots cost a lot at first. Buying and setting up these machines is expensive for small farms. This high price stops some growers from using robots. Farms with less money or help have a harder time. Some reports say semi-autonomous robots cost less and are simpler to use. This helps smaller orchards try robots. Farms need better loans and support to afford robots. Saving money later is possible, but the first cost is still hard.

Note: New ideas and lower prices can help more farms use robots soon.

Technical Barriers

Orchard robots have many problems in real orchards. Thick tree canopies block GNSS signals, so robots get lost. Tight orchard spaces and thick branches make it hard for robots to move. Robots must handle lots of data from LiDAR and cameras. This needs strong computers. Sun and shade changes confuse robot vision. GNSS and IMU help with location but do not show everything around. Uneven ground and weeds make it hard for robots to find paths.

-

Tree canopies block GNSS signals often.

-

Thick branches stop robots and sensors from moving well.

-

Sun and shade changes make vision sensors less clear.

-

LiDAR sensors work worse on bumpy ground.

-

Robots must handle lots of data fast.

-

Weeds and dead trees make object finding harder.

Robots still have trouble picking fruit at the best time. People can see and feel ripe fruit, but robots sometimes miss it.

Integration Issues

Farms must change their work to use orchard robots. Adding new robots to old systems is not easy. Some robots do not fit with old tools or farm layouts. Workers need training to use and fix robots. This takes time and money. Farms must change plans and schedules for robots. Some growers worry about losing control over picking. Farms must fix these problems to get the most from robots.

Tip: Farms can try semi-autonomous robots first to make changes easier.

Workforce Impact

Robots change how many workers farms need. Many farms use robots because there are not enough workers. Robots can pick fruit longer and may replace one worker per hectare. This helps farms save money and finish picking. But some jobs may go away as robots pick more fruit. The change is slow because robots are not as fast as people yet. Farms must think about how robots will change jobs and plan for new work like robot care and data jobs.

Farms can teach workers new skills for robot care and data work.

Precision Agriculture in Smart Orchards

Data Collection

Orchard robots are important for precision agriculture. They collect data as they work. Robots use sensors and cameras to check crops. They look at plant health, soil wetness, and pests. Philip Reece, CEO of InDro Robotics, says robots and drones give updates quickly. This information helps farmers grow more crops and spend less money. Robots also use LiDAR and 3D maps to find fruit trees. They make maps that help them move and make choices. These tools help robots support smart orchards with good data.

Optimized Growth

Robots help plants grow better by giving farmers more details. Mobile robots gather facts about each tree. This helps farmers make better choices and protect nature. Robots work with artificial intelligence and the Internet of Things. They control pests and diseases more carefully. Studies show robots use pesticides well and fit different orchard shapes. These steps keep plants safe and lower pollution. Precision agriculture works better, and plants grow stronger.

Input Management

Multi-function orchard robots use sensors to scan fields for soil wetness, nutrients, and pH. They give water and nutrients only where needed. This cuts down on waste. Automated watering can save over 90% of water. Robots use special fertilizing to treat certain spots. Subsurface watering sends water right to the roots. These ways help farmers save supplies and farm in a better way.

Tip: Robots help manage inputs for healthier crops and lower costs.

Adoption Steps

Readiness

Farmers need to see if their orchards are ready for robots. Some orchard designs work better with robots than others. Orchards with small-canopied trees and vertical trellises help robots pick fruit. These green walls make it easier for machines to work. This design was first made for people, but it helps robots too. Extra pruning and thinning help robots find and pick fruit more easily. Farms that already use these layouts are more ready for robots. Still, robots can miss fruit hidden by leaves or branches. Farms should also check how fruit moves after picking. Conveyor systems inside pickers can help stop fruit from getting hurt.

Tip: Farms with high-density planting and good pruning are ahead with orchard robots.

ROI Analysis

Farmers must see if robots will save money and help their business. A cost-benefit analysis is important for this choice. The steps are:

-

Make different farm plans to see how robots change work and costs.

-

Use partial budgeting to look at changes in labor and equipment costs.

-

Check the whole farm budget to see the big picture.

-

Measure how much less hand work is needed and how much money is saved.

-

Add up the costs for buying, fixing, and training for the robots.

-

Think about how robots work with data systems to help make better choices.

-

See if robots help the farm work better and faster.

-

Find any problems that could stop profits.

Farmers should count both direct and indirect benefits in their study.

Implementation

To use robots well, farms need to be "Robot Ready." High-density planting and tall tree walls help robots move and pick fruit. Farms should use smart sensors, machine vision, and navigation systems. Drones and remote sensors give more data for better choices. Growers who use precision agriculture get better results. Training workers to use and fix robots is also needed. In the future, robots will get better at picking, pruning, and other jobs.

Note: Farms that plan and change their orchards for robots will get the best results.

Farmers notice good things and some problems with orchard robots.

-

Better accuracy, quick data, and earth-friendly actions help smart orchards.

-

Big prices, rough land, and the need for updates still worry farmers.

More farms use robots as tech gets better and help from the government grows. Learning new things and trying new ideas helps farms do well later.

+86-025-87150950

+86-025-87150950 globalsales@sinosorob.com

globalsales@sinosorob.com +86 18133051944

+86 18133051944